Applied Polymer Technology Extension Consortium (APTEC)

Expertise

|

APTEC members include experts in all areas of polymer science and engineering.

*Synthesis

*Theory |

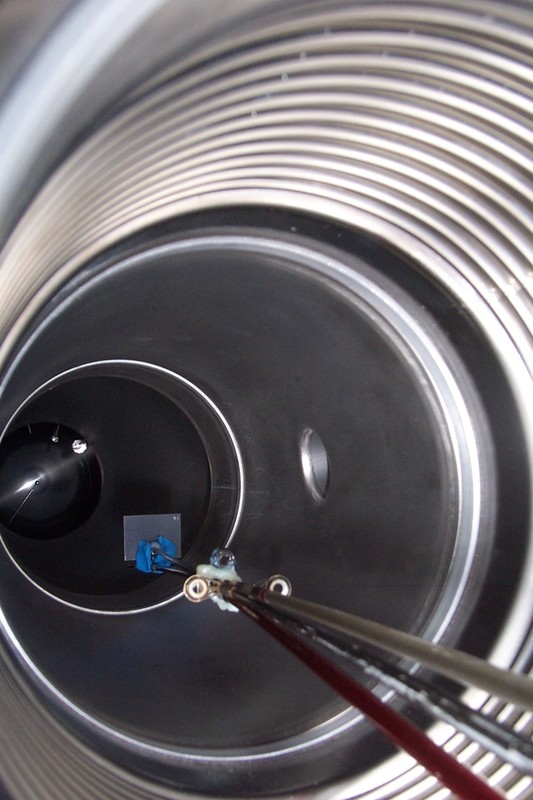

Links to some of the equipment available to APTEC

|

Facilities

APTEC puts users in contact with facilities available to its members, but more importantly it connects users to experts in problem solving.

Molecular weight and size determination: APTEC researchers run active, well-funded labs for almost any polymer molecular weight determination problem. Methods can include classical Zimm plots, analytical ultracentrifugation, osmometry and a full complement of on-line methods such as GPC with multiple-angle light scattering and viscometric detection. The Tulane facility has a great deal of experience with on-line monitoring during polymerization process itself.

Particle sizing: APTEC has an especially high concentration of researchers who specialize in thorny particle sizing problems, both in liquid and powder form. Dynamic light scattering, low-angle particle scattering, microscopy, zeta potential and particle tracking are available.

Thermal properties: APTEC coordinates several labs with much expertise in differential scanning calorimetry, including the latest modulated DSC methods. Glass transitions, melting points, "melt crystallization", percent crystallinity and thermal stability are well understood here. Thermogravimetric analysis is performed routinely. Solution calorimetry and titration calorimetry are also available.

Bulk mechanical measurements: Strength, elongation, shear and creep can be measured on various size scales.

Rheology: storage and loss moduli can be determined in liquid samples and melts.

Imaging: Whether it be polarized optical microscopy for determination of spherulitic structures or cryo-TEM to evaluate soft, self-assembled structures, APTEC can put users into contact with excellent light microscopy and electron microscopy facilities.

Scattering: In addition to scattering of visible light from solutions, APTEC members are frequent users of small-angle X-ray and neutron scattering facilities at LSU's dedicated synchrotron (CAMD) and other national and international facilities.

Molecular weight and size determination: APTEC researchers run active, well-funded labs for almost any polymer molecular weight determination problem. Methods can include classical Zimm plots, analytical ultracentrifugation, osmometry and a full complement of on-line methods such as GPC with multiple-angle light scattering and viscometric detection. The Tulane facility has a great deal of experience with on-line monitoring during polymerization process itself.

Particle sizing: APTEC has an especially high concentration of researchers who specialize in thorny particle sizing problems, both in liquid and powder form. Dynamic light scattering, low-angle particle scattering, microscopy, zeta potential and particle tracking are available.

Thermal properties: APTEC coordinates several labs with much expertise in differential scanning calorimetry, including the latest modulated DSC methods. Glass transitions, melting points, "melt crystallization", percent crystallinity and thermal stability are well understood here. Thermogravimetric analysis is performed routinely. Solution calorimetry and titration calorimetry are also available.

Bulk mechanical measurements: Strength, elongation, shear and creep can be measured on various size scales.

Rheology: storage and loss moduli can be determined in liquid samples and melts.

Imaging: Whether it be polarized optical microscopy for determination of spherulitic structures or cryo-TEM to evaluate soft, self-assembled structures, APTEC can put users into contact with excellent light microscopy and electron microscopy facilities.

Scattering: In addition to scattering of visible light from solutions, APTEC members are frequent users of small-angle X-ray and neutron scattering facilities at LSU's dedicated synchrotron (CAMD) and other national and international facilities.

Site powered by Weebly. Managed by iHost Networks